Metal Sheets Coated with Copper and Lead

Lead-Coated Copper Sheet Metal: A Durable Choice for Harsh Environments

In the realm of construction materials, lead-coated copper sheet metal stands out as an exceptional alternative to regular copper, particularly in environments prone to corrosion. This innovative material combines the advantages of copper's high thermal and electrical conductivity with the protective, acoustic, and shielding qualities of lead.

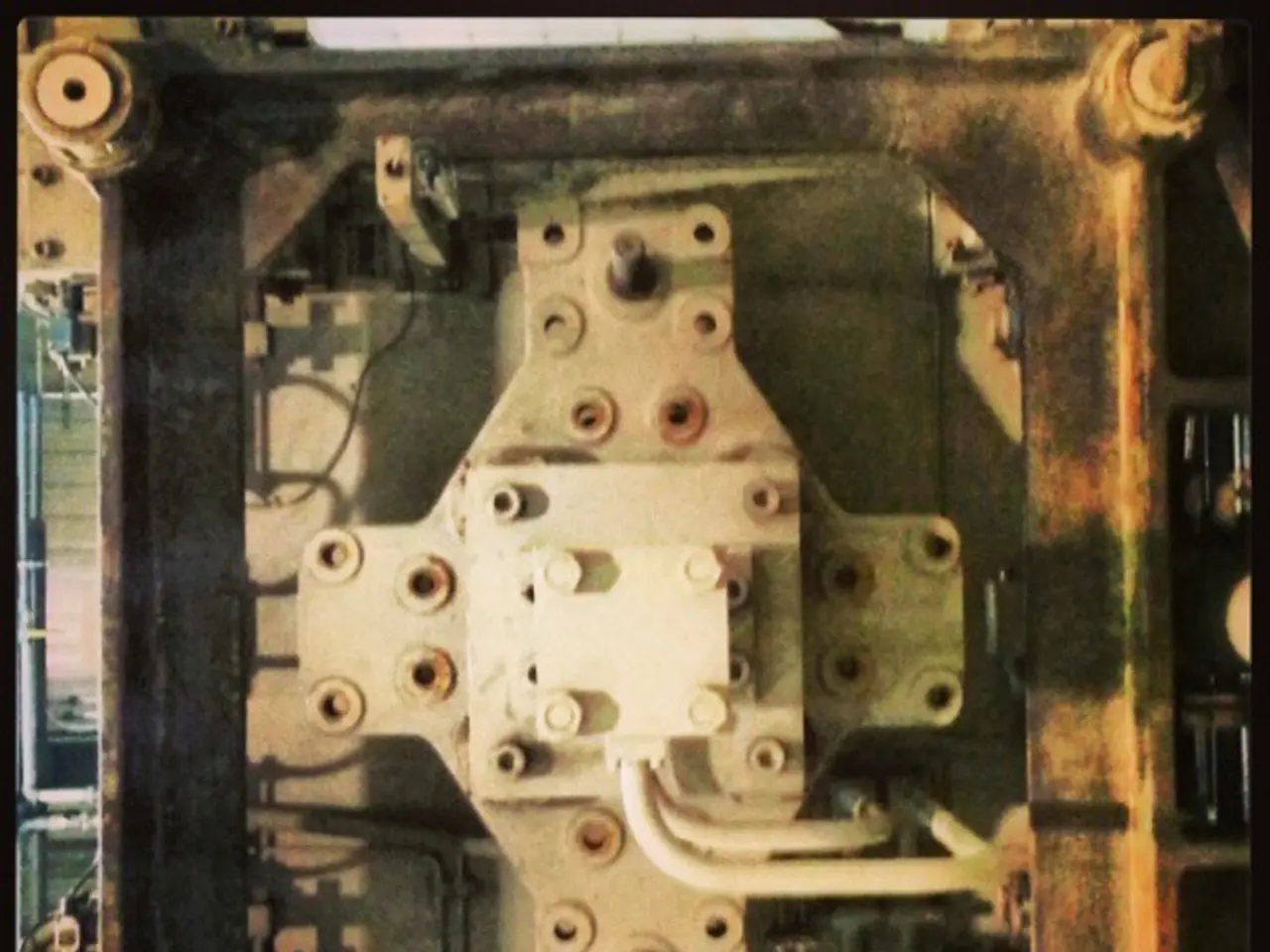

Lead, when used in construction, is dense, brittle, has a low melting point, and is easily cast. However, in the process of electroplating, a thin layer of lead is applied to a sheet of copper, creating lead-coated copper. This layer provides enhanced resistance to corrosion, oxidation, and environmental degradation, extending the lifespan of the material in construction applications.

One of the primary advantages of lead-coated copper is its improved corrosion resistance. The lead coating protects the copper substrate underneath, reducing maintenance and replacement frequency. The enhanced durability of lead-coated copper is evident in its suitability for coastal construction projects, where it can withstand salt spray and other corrosive elements.

In addition to its corrosion resistance, lead-coated copper also offers sound and vibration dampening properties. Lead's high density and damping properties can reduce sound transmission and vibration when incorporated in building assemblies, providing acoustic benefits not present in bare copper. Furthermore, lead-coated copper has potential radiation shielding qualities due to its high density and attenuation abilities, although this is more relevant in specialized applications.

The machinability and workability of lead-coated copper can also be improved compared to regular copper, aiding fabrication processes such as bending or shaping. Copper and lead-coated copper sheet metals are available in a variety of thicknesses and widths, with the thickness determining the weight and durability, and the width affecting the coverage area.

Common applications in construction of lead-coated copper sheet metal include architectural elements requiring enhanced longevity and protection from weathering, such as roofing, cladding, flashing, gutters, and roof parapets. It is also beneficial in areas where sound insulation or vibration damping is beneficial, such as walls, floors, and ceilings in sound studios or quiet zones. Lastly, lead-coated copper can serve as a protective layer for copper structures exposed to aggressive environmental or chemical conditions, prolonging service life without sacrificing copper’s corrosion resistance.

Regular copper sheet metal, while highly valued for its excellent corrosion resistance, high thermal and electrical conductivity, and aesthetic appeal, can be softer and more prone to mechanical damage. In harsh environments, additional coatings or treatments may be required to ensure its longevity. In contrast, the lead coating on lead-coated copper provides an additional layer of protection, making it a more robust choice for specific construction scenarios where enhanced durability, noise control, and environmental resistance are critical.

For more information about Heather & Little's restoration services for lead-coated copper sheet metal, contact them directly. Heather & Little specializes in the restoration of all types of sheet metal, including copper and lead-coated copper, using the latest technologies and methods. Their services cover a wide range of features, such as domes, steeples, decorative elements, statues, metal-clad windows and doors, and more. A properly installed copper roof can last up to 75 years, and the addition of a lead coating can further extend its lifespan.

In conclusion, lead-coated copper sheet metal offers a durable and versatile solution for construction projects, particularly in environments where regular copper might degrade faster. Its enhanced properties make it an excellent choice for coastal construction projects, sound studios, and structures exposed to aggressive environmental or chemical conditions.

The manufacturing process of lead-coated copper sheet metal combines elements from the construction, technology, and finance industries, as the thin layer of lead is applied through electroplating. The protected copper substrate within lead-coated copper enhances the material's potential applications in various sectors, such as finance, due to its increased lifespan in construction, which may lead to reduced maintenance costs. In addition, the sound and vibration dampening properties of lead-coated copper make it viable for technology-oriented environments, such as sound studios.