Exploring the Potential of Magnets: A Look into Groundbreaking Motor Technology

The Revolution of Magnetic Motors: A Promising Future for Efficiency and Sustainability

Magnetic motors, an innovative technology, are making waves in various industries with their potential for increased efficiency and reduced maintenance costs. These motors operate by generating motion through the interaction of magnetic fields produced by permanent magnets and electromagnets.

In a typical electric motor, a current flowing through coils creates an electromagnet (rotor), which interacts with the magnetic field of stationary magnets (stator), producing a torque that causes rotation. This continuous rotation is maintained by changing current direction (commutation) to keep the torque in the same rotational direction. Synchronous motors, for instance, use three-phase currents in the stator producing a rotating magnetic field that the rotor locks onto and rotates synchronously with.

Everyday conveniences like electric toothbrushes, washing machines, and induction cooktops already benefit from magnetic motors. Moreover, they drive innovations such as self-driving cars and renewable energy turbines. Magnetic bearings can replace traditional bearings, eliminating friction and enhancing efficiency.

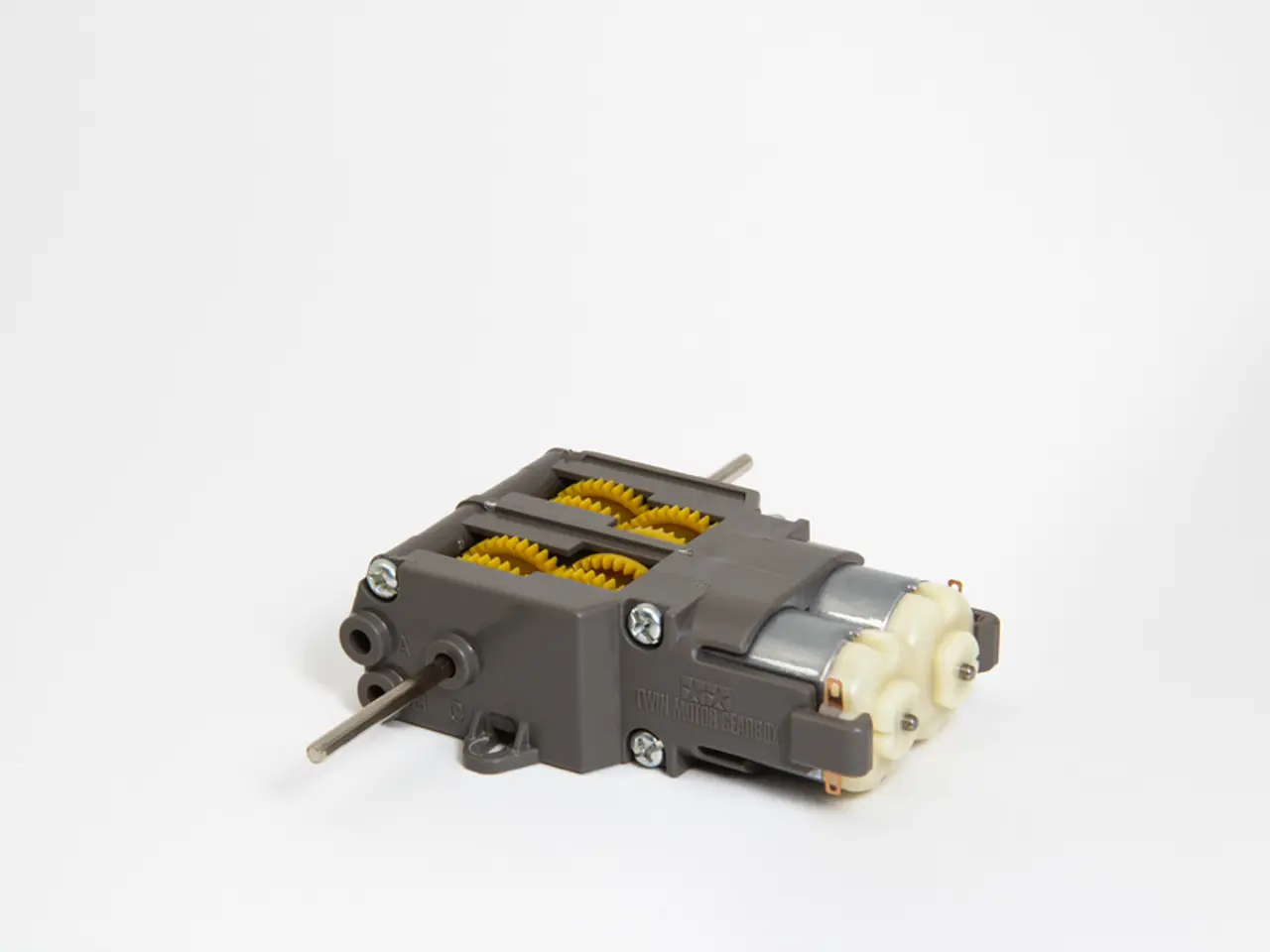

Magnetic motors are dominant in electric vehicle (EV) drivetrains and industrial machinery due to their efficiency and power density. Permanent magnet synchronous motors and induction motors are particularly popular in these applications. High torque DC motors, which use permanent magnets and multiple coils, are essential for applications needing high torque output, such as robotics and automation.

New motor types like inductive motors (with conductive bars instead of magnets) reduce reliance on rare-earth magnets, addressing supply chain and cost issues, particularly relevant for EVs. The future of magnetic motors includes significant advancements in miniaturization, efficiency, and integration across various applications.

Efficient energy storage is crucial for future magnetic motor development. Batteries and supercapacitors play integral roles in this regard. Innovations aim to overcome limitations of induction motors (lower torque density) and permanent magnet motors (cost and supply vulnerabilities) by combining advanced materials and design improvements.

Enhanced electronic control and new commutation techniques improve continuous rotation and torque in magnetic motors, leading to more compact, efficient, and high-torque designs. Emerging electrostatic motors, which use electrostatic force instead of magnetic fields, offer higher efficiency and reduced material costs but are still in experimental stages.

Future trends are moving toward reducing reliance on rare-earth magnets with new magnet-free and electrostatic motor technologies that promise higher efficiency, lower costs, and improved sustainability. Motors using electrostatic forces, for example, promise ultra-high efficiency (~98%), significant reduction in copper use, and lower energy losses, representing a major technological shift from traditional magnetic motors.

In summary, the potential of magnetic motors expands as science evolves, promising a future where magnetic drives are as ubiquitous as sunlight. Direct magnetic interaction can deliver power without gear energy bottlenecks. Electrical motors use magnetism to generate torque and motion, consisting of a stator and a rotor. Magnetic motors offer potential for higher efficiency, lower noise production, and reduced maintenance costs compared to traditional electric motor technology. These advances position magnetic and alternative motors at the core of next-generation electric mobility and industrial innovation.

- In the realm of science and technology, magnetic motors, due to their efficiency and reduced maintenance costs, are becoming increasingly significant, particularly in next-generation electric mobility and industrial innovation.

- With advancements in science, the application of magnetic fields in motors is expected to become as ubiquitous as sunlight, offering potential for higher efficiency, lower noise production, and greater sustainability compared to traditional electric motor technology.