Exploring the Decision Between Off-the-Shelf and Customized Blending Vessels: An Evolution of Expansion and Technology Advancements

Stepping foot into your production zone should feel like having the perfect equipment that caters to your unique needs. It's not just about any mixing tank, but the mixing tank that fits like a glove. Customizing mixing tanks might seem daunting, but making the leap can revolutionize your manufacturing process in incredible ways.

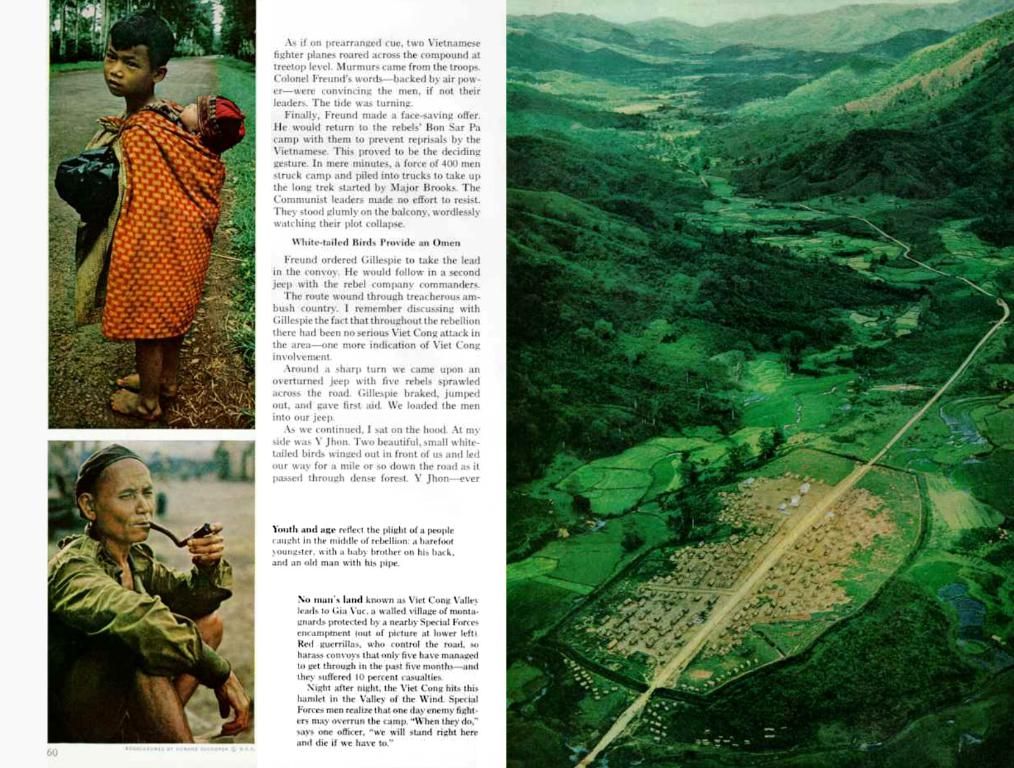

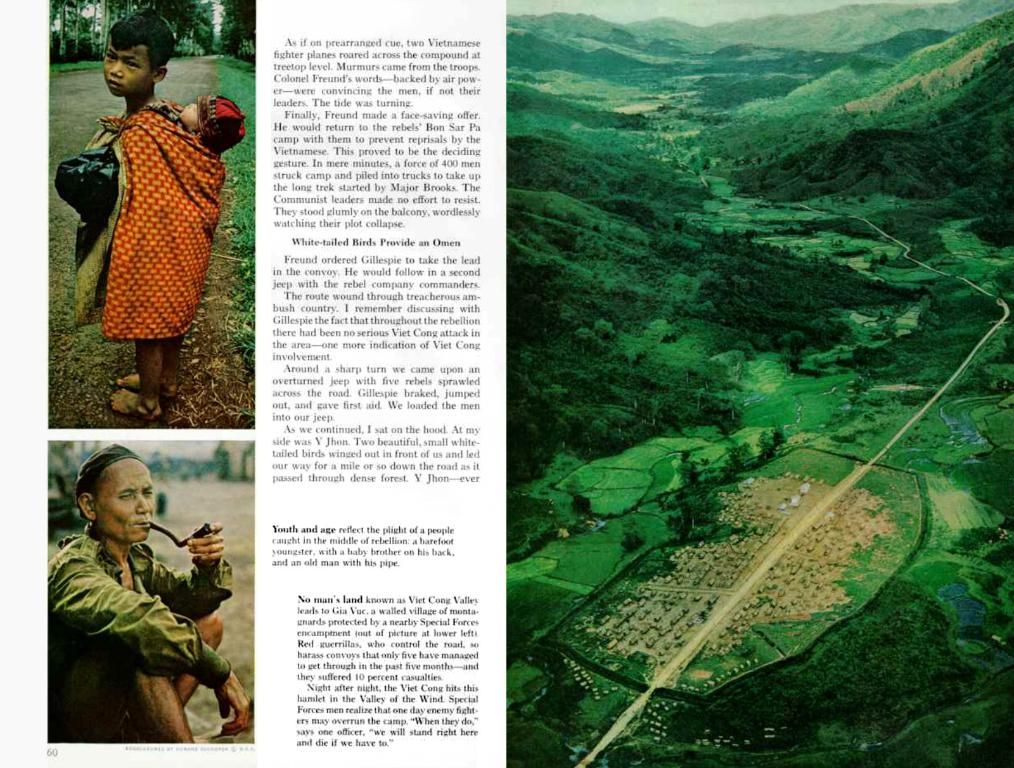

These bespoke solutions empower you to fine-tune your operations, ensuring they cater to your distinct needs while effectively scaling your production. Consider the scenario where you're in a culinary setting, dealing with delicate flavors, or the chemical production realm with robust materials. The ability to customize lets you deliver top-notch products while maintaining operational efficiency.

Off-the-shelf, standard mixing tanks, designed for common industry needs, can seem like a convenient solution. They are produced in bulk, ready to deliver, which can speed up production without delay. However, their one-size-fits-all designs may lack the flexibility required to cater to unique production specifics.

In my personal experience, a standard mixing tank for a specialized product line simply couldn't cut it. It failed to deliver the consistency and quality we were aiming for. This prompted me to venture into custom solutions, and I can honestly say it was an enlightening journey!

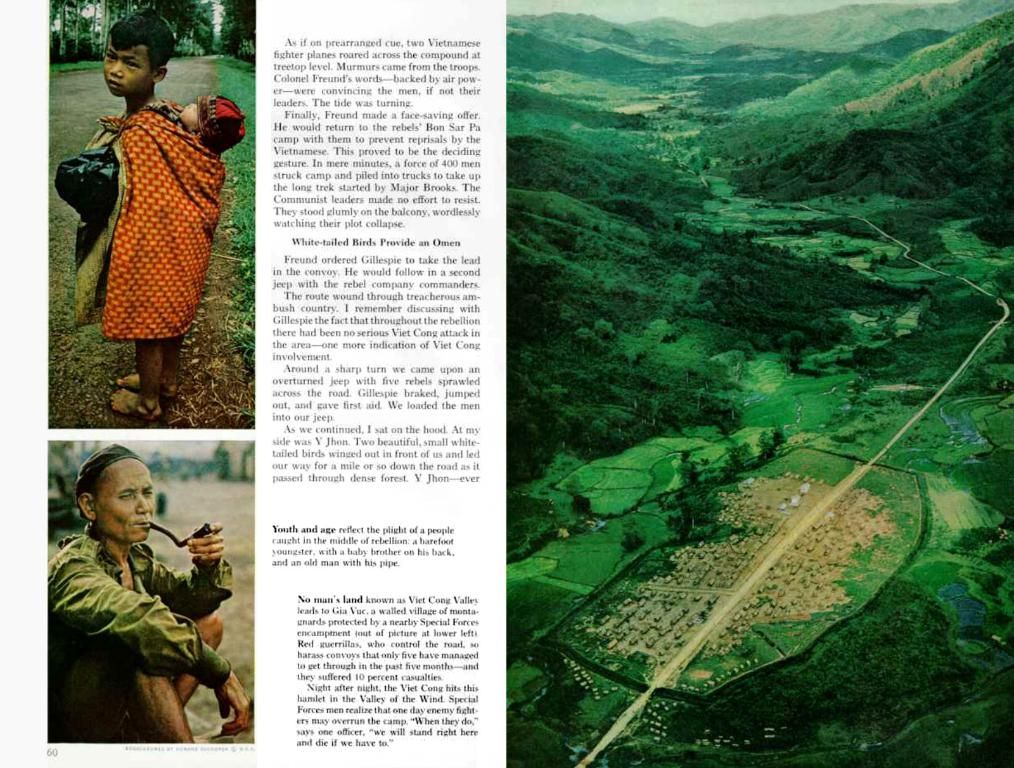

Scalability is crucial in production. Standard tanks may work fine for straightforward production lines, but what happens when we need to pivot? Custom mixing tanks offer a significant advantage in scalability. They can be tailored to grow alongside your business, ensuring seamless transitions as your needs evolve.

Nurturing strong relationships within your team and with your suppliers cannot be overstated. The decision between custom and standard mixing tanks is a reflection of team dynamics and supplier partnerships. By collaborating on custom solutions, we foster an environment of open communication and teamwork, resulting in flourishing relationships.

When navigating the sea of choices between standard and custom mixing tanks, remember that every tank carries a narrative filled with challenges, victories, and everything in between. Your decision can elevate your business to new heights, making every tank a significant investment in your unique vision.

For a deeper dive into this topic, you can visit this carefully selected external resource. Mixing tanks: Optimise your production today!

- The evolution of manufacturing can be spurred by adopting smart AI systems in the design and automation of custom mixing glass systems.

- These tailor-made mixing tanks are not only innovative solutions for catering to specific production needs but also pave the way for scaling in the finance and technology-driven industry.

- Embracing custom mixing glass systems can revolutionize your manufacturing process, as they offer the flexibility to handle delicate culinary tasks or robust chemical production demands.

- Opting for standard, off-the-shelf mixing tanks, while seemingly efficient due to their speed and affordability, may lack the necessary adaptability for meeting unique production requirements.

- Venturing into custom solutions can lead to enhanced operability and product quality, as witnessed in my personal experience with a specialized product line.

- Nurturing strong relationships with your team and suppliers is essential when making the decision between standard and custom mixing tanks, fostering an environment of open communication and teamwork to sustain business growth and success.