Mastering Autonomous Maintenance (AM) within the Total Productive Maintenance (TPM) Ramble

Comprehensive Handbook for Effective Autonomous Maintenance Operations

What's the Lowdown on AM and TPM?Get ready to saddle up as operators take the reins of equipment care—that's what Autonomous Maintenance (AM) is all about. This badass approach falls squarely within the Total Productive Maintenance (TPM) movement, helping your machinery stay purring perfectly, slashing downtime, and amping up production efficiency[1][3].

The Deets: What Operators Are Here for

- Operator In-volu-me: Equipping operators to tackle daily maintenance tasks is like giving them superpowers—they'll nab problems as soon as they pop up.

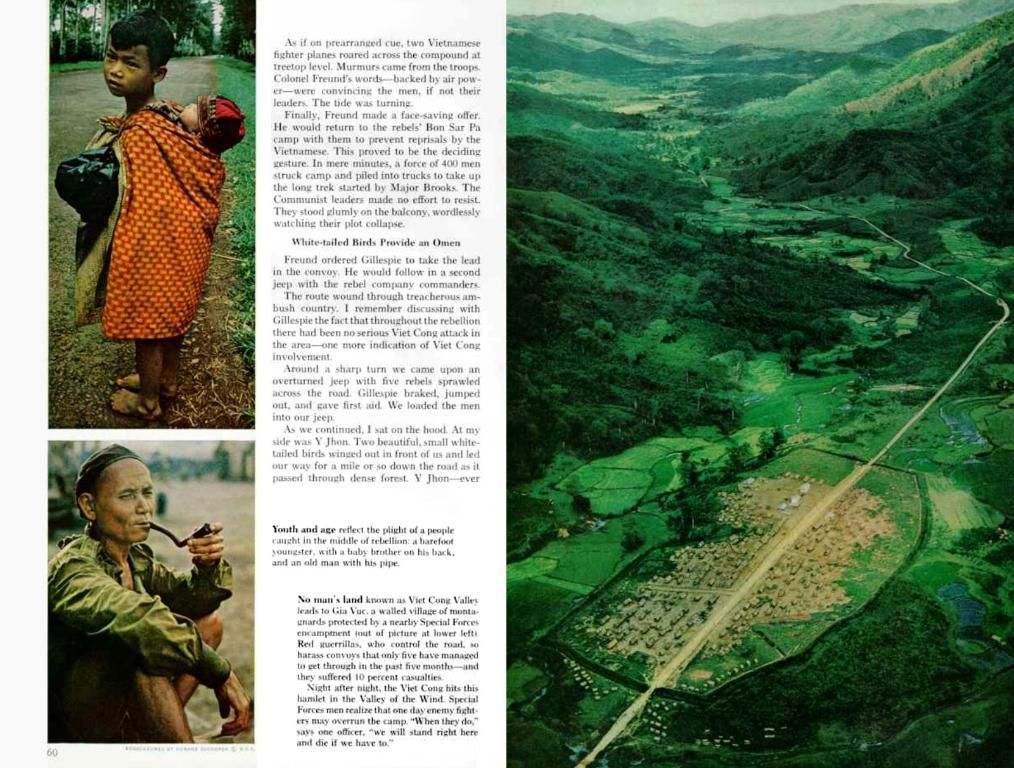

- Prevention Party: Routine checks? More like detective work. Operators dig up and squash glitches before they go in for the kill, minimizing the wear and tear on equipment.

- Efficiency Boost: Healthy gear on the double! Continuous vigilance guarantees top-notch performance, extending the lifespan of equipment[1][3].

How to Execute and Maintain AM

Warm up: On-boarding and Encouragement

- Training Sesh: Time to school your operators in maintenance routines, and let them flex those troubleshooting muscles.

- Skin in the Game: Encourage operators to step up and make their tools second nature—these babies are their responsibility now!

Set the Standards: Regulations and Documentation

- Marching Orders: Been there, standardized that! Ensure consistency across teams and shifts with standardized maintenance procedures.

- History Book: Keep a record of all maintenance activities to help you trace and improve performance.

Progress Report: Continuous Growth

- Scoreboard Watching: Regularly review and revise maintenance protocols based on feedback and tasty insights.

- Feedback Loop: Foster an environment that encourages constant improvement—you're always your own harshest critic, right?

Surviving and Thriving with AM

Quality Control: Regular Audits**

- Tally Ho: Periodically conduct audits to make sure everyone's sticking to the playbook.

- Correction Station: Nip any deviations in the bud, and you'll maintain that consistency like a boss.

The Motivation Station: Celebration and Rewards**

- High-Fives Galore: Recognize the champions among your operators who ace the maintenance game.

- Hall of Fame: Show off your success Stories to fire up the team and reinforce the importance of AM.

Game Changers: Digital Tools

Enter Weever: Simplifying AM Tasks**

- Task Force: Use digital platforms to create orderly workflows and tic-mark lists for maintenance tasks, ensuring precision every step of the way.

- Track Star: Keep an eye on maintenance activities via digital logs to track performance and make improvements like a pro.

Real-time Action and Alerts**

- Early Warning System: Implement real-time monitoring systems that scan machinery for abnormalities or hiccups before they catch you with your pants down.

- Speedy Response Unit: Alert the right teams to take action pronto, minimizing downtime like a SEAL team.

Data-Driven Discoveries**

- Smart Analytics: Use data analytics to divulge juicy insights into equipment behavior, helping you optimize schedules, and improve overall equipment effectiveness.

Digital tools like Weever are more than mere sidekicks—they're the secret ingredient in amping up the implementation and longevity of AM by offering up a centralized command post for ruthless maintenance task management, real-time monitoring, and data-crunching genius[5]. Conquering AM means taking your plant from zero to hero!

- By educating operators on maintenance routines and empowering them to take responsibility for equipment care, we can effectively execute autonomous maintenance (AM) within the Total Productive Maintenance (TPM) framework.

- To maintain the consistency of AM, it's crucial to establish standardized maintenance procedures and digital logs to track all activities, utilizing tools like Weever for precision and real-time monitoring.

- Encouraging operators to regularly review and revise maintenance protocols, fostering an environment that prioritizes constant improvement, ensures that the manufacturing industry can continuously thrive and grow.

- Implementing data-driven solutions, such as real-time monitoring systems and smart analytics, allows finance and technology sectors to optimize schedules, improve overall equipment effectiveness, and drive success in the manufacturing industry.